- Stock: 24

- Model: KP5

- Weight: 0.42kg

- Dimensions: 78.00mm x 76.00mm x 76.00mm

- SKU: KP5

- UPC: 6009600401884

Spindle

cutter - Full bead/Half round/Bull nose 3/4'

Spindle

cutter - Full bead/Half round/Bull nose 3/4'

Tungsten Carbide - 3 wing

The cutter is designed to be used with a stationary spindle moulder equipped with either a 3/4' or 1/2' spindle shaft.

The cutter can be configured to cut full beads, half rounds or a bull nose.

KP800020 - 3/4' - 1/2' spacer rings

Important:

- Make sure the spindle moulder has a table opening of at least Ø 140mm.

- Designed for spindle moulders equipped with either a 1/2' or 3/4' spindle shaft.

Spindle Safety

Spindle cutters can potentially be dangerous and should deserve your attention and respect.

Use push sticks or a push block to position your hands a safe distance from the spindle cutter.

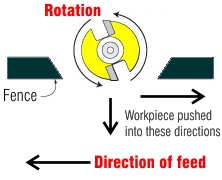

Never climb-cut. Always feed the stock against the rotation of the cutter (see illustration).

Avoid moulding small stock. Instead, mould a larger piece and cut it to size afterwards.

Always use a guard. If the fence didn’t come with a guard, make your own.

Never start the spindle with the cutter in contact with the material.

Don’t force the cutter or overload the machine. Excessive heat is an enemy.

The spindle moulder needs to have a power feeder or feather boards fitted to apply sufficient feeding pressure.

Fit the cutter on the lowest point of the spindle shaft.

Be sober and not under the influence of medicine that causes a lack of concentration.

Make sure the spacer rings on the spindle shaft are locked in place correctly.

Tidy up your workshop to ensure the ability to move freely with enough room around the spindle moulder.

| consider safety for your health and the people around you | |||

General safety suggestions:It is advisable to always have the following items nearby and in a good condition

|

|||

|

|

|

|

|

|

Wear Gloves

|

Eye Protection

|

Hearing Protection

|

Dust Mask

|

To use spindle cutters safely (and to get the best results from your spindle), the cutters need to be installed properly on the spindle shaft. Improper installation of your cutter can cause excessive chatter and could increase the likelihood that the bits will break when in use. There is also a risk of having the cutter 'cold welded' to the spindle shaft.

First of all, before beginning any moulding operation, check your cutter to make sure that it is clean and most of all, sharp. If the bit is dull, chipped, is excessively burnt or has any other defect, it should be sharpened or replaced before use.

| Description | Specification |

| Cutter profile | Full bead/Half round/Bull nose |

| Width | 3/4' |

| Arbor | 3/4' |

| Wings | 3 |