Out Of Stock

DIG. CALIPER 200MM 0.02MM ACC. CERAM. JAWS S/STEEL 0.01MM RES.

R 3,296.00

Ex Tax: R 2,866.09

| Quantity | Unit Price | You Save |

|---|---|---|

| 3 or more | R 3,173.41 | 3.72 % |

| 6 or more | R 3,100.17 | 5.94 % |

- Stock: Out Of Stock

- Model: AC115-008-11

- Weight: 0.55kg

- Dimensions: 317.00mm x 120.00mm x 34.00mm

- SKU: AC115-008-11

- UPC: 6009515892272

For 10 or more items, click to quote

Digital Vernier Caliper with Ceramic Jaws 200mm

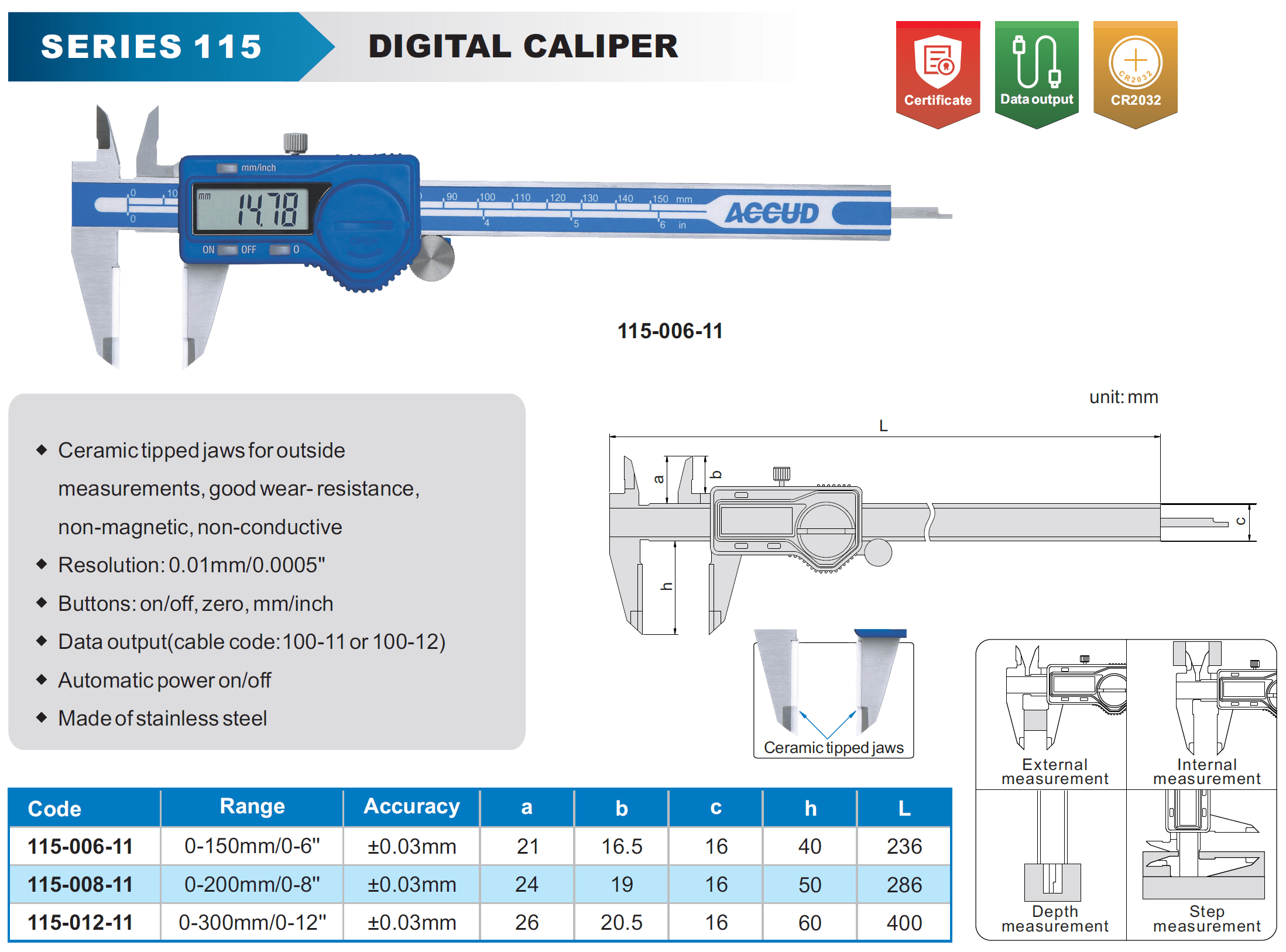

SERIES 115

SERIES 115

The digital caliper with ceramic jaws is a precision measuring tool designed for specific applications where the use of non-metallic materials is crucial. Ceramic jaws offer unique properties such as non-conductivity, corrosion resistance, and scratch resistance, making these calipers ideal for specialized environments.

- Ceramic tipped jaws for outside measurements, good wear- resistance, non-magnetic, non-conductive

- Resolution: 0.01mm/0.0005'

- Buttons: on/off, zero, mm/inch

- Data output (cable code:100-11 or 100-12)

- Automatic power on/off

- Made of stainless steel

Advantages of Ceramic Jaws:

- Non-Scratching: The ceramic jaws prevent scratching on soft or delicate surfaces, such as glass, polished metals, or plastics.

- Corrosion Resistance: Ceramic jaws are highly resistant to chemicals, moisture, and other corrosive elements, making them suitable for harsh environments.

- Non-Conductive and Non-Magnetic: Perfect for measuring electrically sensitive or magnetic parts without causing interference or damage.

- Durability: Ceramic is extremely hard, which ensures long-lasting sharpness and wear resistance.

Applications:

- Electronics and Semiconductors: The non-conductive and non-magnetic properties of ceramic jaws make these calipers ideal for measuring electronic components, semiconductors, and circuit boards.

- Medical Devices: Often used in the medical industry for measuring delicate instruments or parts, where contamination or damage from metal calipers must be avoided.

- Precision Engineering: Used in high-precision applications such as aerospace, optics, and engineering where scratch resistance and precise measurements are critical.

- Chemical and Food Industry: The corrosion resistance of ceramic jaws makes them suitable for environments where the caliper may come into contact with aggressive chemicals or food-grade materials.

How to use:

- Position the Jaws: The user moves the jaws of the caliper to fit the object being measured.

- Measurement Display: The digital sensor inside the caliper detects the distance between the jaws and displays the measurement on the screen in real-time.

- Switch Units: Measurements can easily be switched between millimeters and inches with the push of a button.

- Zero Function: Pressing the zero button resets the display to zero at any point, allowing for differential measurements.

Uses:

- External Measurements: The external jaws are used to measure the outside dimensions of objects like shafts, rods, and blocks.

- Internal Measurements: The internal jaws measure the inner diameter of holes, tubes, and other hollow objects.

- Depth Measurement: The depth rod is used to measure the depth of holes or recesses.

- Step Measurement: Measures the height difference between two surfaces.

A digital caliper is an essential tool for professionals and hobbyists alike, offering precise, easy-to-read measurements for a variety of applications.

Features at a glance

- Digital display: Provides precise and easy-to-read measurements.

- Accuracy: High level of accuracy

- Versatility: Can be used for various measurement tasks (external, internal, depth).

- Compact design: Easy to carry and use.

- Eliminates reading errors: The digital display prevents misinterpretation of the scales.

- Faster measurements: The digital readout is immediate.

- Increased accuracy: Often provides higher precision than traditional vernier calipers.

Digital Vernier Caliper AC115 Series